Usage Examples

Find out our use cases

Why choosing the electrolytic marking?

How to mark any type of metal regardless of its hardness? Which type of marking choosing in order to keep the piece intact and to faithfully and indelibly reproduce the desired logos and/or the identification codes?

Zaniboni electrolytic marking system guarantees a precise, indelible and fast marking.

In order to guarantee the maximum efficiency, in fact, the Zaniboni has a reliable and efficient production system of stencils and electrolytic liquid which allows the electrolytic process.

Zaniboni electrolytic liquid

The electrolytic liquid is made of 75% by water and 25% by conductor salts and allows an indelible marking on metals. Furthermore, oxidation phenomena of the materials are avoided thanks to its composition which doesn’t contain any acid substances. For the same reason neutralizing liquids are not necessary.

Zaniboni Stencils

The other needful item in an electrolytic marking system is the stencil which reproduces faithfully the writings and/or logos that one has to mark on the piece. The Zaniboni offers to you three different types of stencils: plastic, photoengraved and cartridges.

Advantages of the electrolytic marking system

Choosing to use the electrolytic making on your metals brings you several advantages.

Herewith you can find the main ones:

Cheap

The electrolytic marking system is a cheap, simple and indelible process.

Performing

This system does not damage, weaken or corrode the metal parts it comes into contact with as the molecular structure of the object is not altered, no matter how deep you go. Furthermore, it does not cause material residues that can alter the marked surface nor micron-cracks that are created as a result of thermal stress and which can damage the mechanical properties of the materials and consequently can cause fractures in the metals.

Versatile

The electrolytic marking system is particularly suitable to be used in fields such as the Aeronautical and Healthcare industries and to mark all the surfaces with close tolerances.

Inalterabile

Furthermore, the main advantage that distinguishes the electrolytic marking system from all the other ones is the fight against counterfeit since the stencil, the element which all the electrolytic process is based on, is very difficult to be realized.

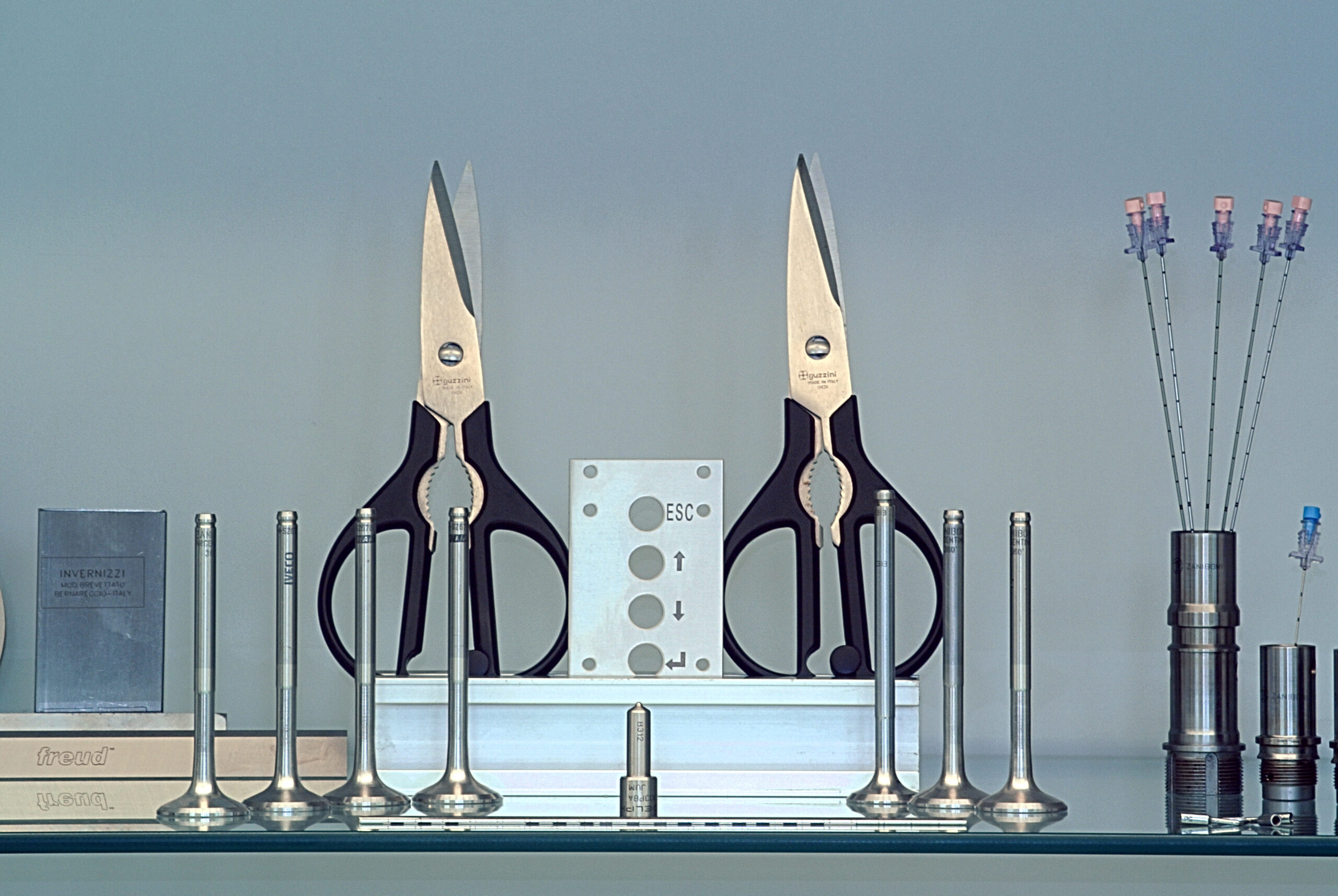

Usage examples

We show you some examples marked using the electrolytic marking system. Each of these fields has chosen the electrolytic marking system because of its numerous advantages.